KUMAR METAL INDUTRIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KUMAR METAL INDUTRIES P.LTD.

Conditioning Cooking

To correctly cook and condition the material prior to Flaker. Vertical, multi-stage unit with fabricated shell and trays where heating is carried out by indirect steam. The gates operated by mechanical level system automatically control the flow of material and the level in each stage. A central shaft driven by a gearbox carried agitator blades to ensure a good mix, a homogenous treatment of the material and prevents burning on the stage bottoms. A vertical duct extracts exhaust vapors from each stage. Provision is made to adjust final moisture levels of the material by injecting water or direct steam.

Huller Shaker

Huller Shaker is a machine where kernel is separated from the seed & the hulls are separated from the kernel. In this process, one can increase the capacity of the machine by doing de-hulling as well decrease the down time of the machine. This process is mainly used in case of Cotton Seed / Sunflower.

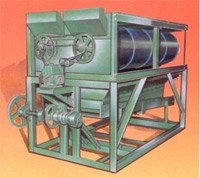

Double Drum Hull Beater

Description / Specification of Double Drum Hull Beater

We are involved in offering a wide range of Double Drum Hull Beater to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Double Drum Hull Beater. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Extraction

Horizontal Model comprising of articulated band conveyor assembly, which receives the material from the Feed Hopper and transport, it at a very slow predetermined speed from the feed to the discharge end. The conveyor moves over the rails suitably located inside the Extractor and the rides on specially constructed sprocket at either end, adjustable damper for regulation of the height of the bed of material on the chain conveyor, series of Spray breakers for the perfect spray of the solvent on the moving bed, with liberal provision for light sight glasses. Band Conveyor Assembly designed in such a way to act as filter bed for eliminating fines, complete with rotary brushes & mesh cleaning system for effective cleaning of mesh

Desolventising Toasting

Vapor tight construction in carbon steel, for de-solventising as well as toasting, specially designed for oilcake and comprising of a number of stages with bottoms jacketed for the purpose of indirect heating. Centrally rotating shafts provided with scrappers along with sparge steam distribution to ensure uniform heating and movements of the materials in the stages. Fitted with indicators to indicate the level of material in the stages. Final discharge door is later connected with the feeding, complete with driving mechanism. With Pneumatic Meal Level Controlling arrangement.

Distillation

To correctly cook and condition the material prior to Flaker. Vertical, multi-stage unit with fabricated shell and trays where heating is carried out by indirect steam. The gates operated by mechanical level system automatically control the flow of material and the level in each stage. A central shaft driven by a gearbox carried agitator blades to ensure a good mix, a homogenous treatment of the material and prevents burning on the stage bottoms. A vertical duct extracts exhaust vapors from each stage. Provision is made to adjust final moisture levels of the material by injecting water or direct steam.

Meal Conditioning

Description / Specification of Meal Conditioning

We are involved in offering a wide range of Meal Conditioning to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Meal Conditioning. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.